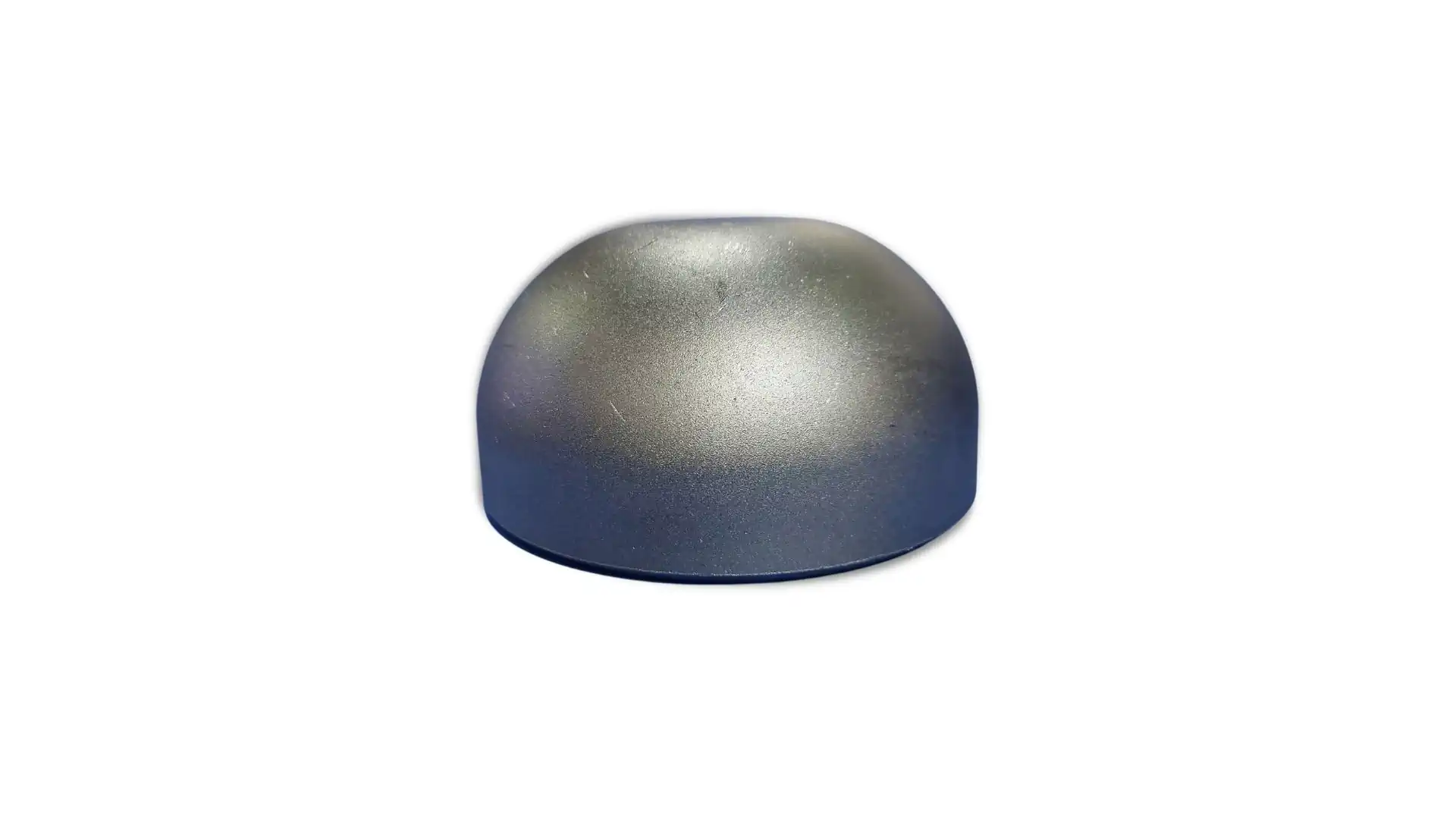

Butt Weld Cap

Butt weld cap and their applications;

Butt weld fittings offer various advantages over other fittings. Butt weld causes less material usage, which means lower material cost and lower weight. Also it permits greater freedom in designing the layout, less space, but greater strength.

Typically, liquid or gas-tight caps seal the open end of a pipe. A cap is attached to the end of the line to be terminated in the pipelines, so that the flow is terminated.

Milfit Boru is increasing our seamless steel cap production and stock capacity every day in line with the demands and needs of our valued customers.

Butt weld cap and their applications;

Butt weld fittings can be used in a wide variety of industries to alter, divide or end the flow of fluids. Butt weld Caps are used in many areas, including the following areas:

- Oil and gas industries

- Shipyards ( Shipbuilding )

- Power Plants

- Food Factories

- Boiler Installations

- Chemical Processing

- Steel Processing

Wall Thickness of Butt Weld Caps : SCH STD – SCH 20 – SCH 40 – SCH 80 – SCH XS – SCH XXS – EN NORMS

CAP

- Standard: ASME B16.9, EN 10253-1/ EN 10253-2 / DIN 2617 Cap

- Material: ST 35.8 – 37 – 44 – ASTM A234 WPA – WPB – S235/ P235 – S265 / P265 Cap

- Temperature: -30° to 425°

- Surface: Black paint / Protective oil / Galvanized/ Sandblasted/ Bare surface Cap

Call For Offer

+90 262 751 53 60

We Manufacture Seamless Steel Pipe & Butt-Weld Fittings

#Dikişsiz #Çelik #Dirsek #Fittings #Sandblasting16″ Çelik Dirsek Basma İşlemi #boru bağlantı elemanları

#Dikişsiz #Çelik #Dirsek Kumlama Pipe #Fittings #Sandblasting #boru bağlantı elemanları

#Dikişsiz #Çelik #Dirsek Markalama #Steel #Elbow Marking #fittings #marking #boru bağlantı elemanları